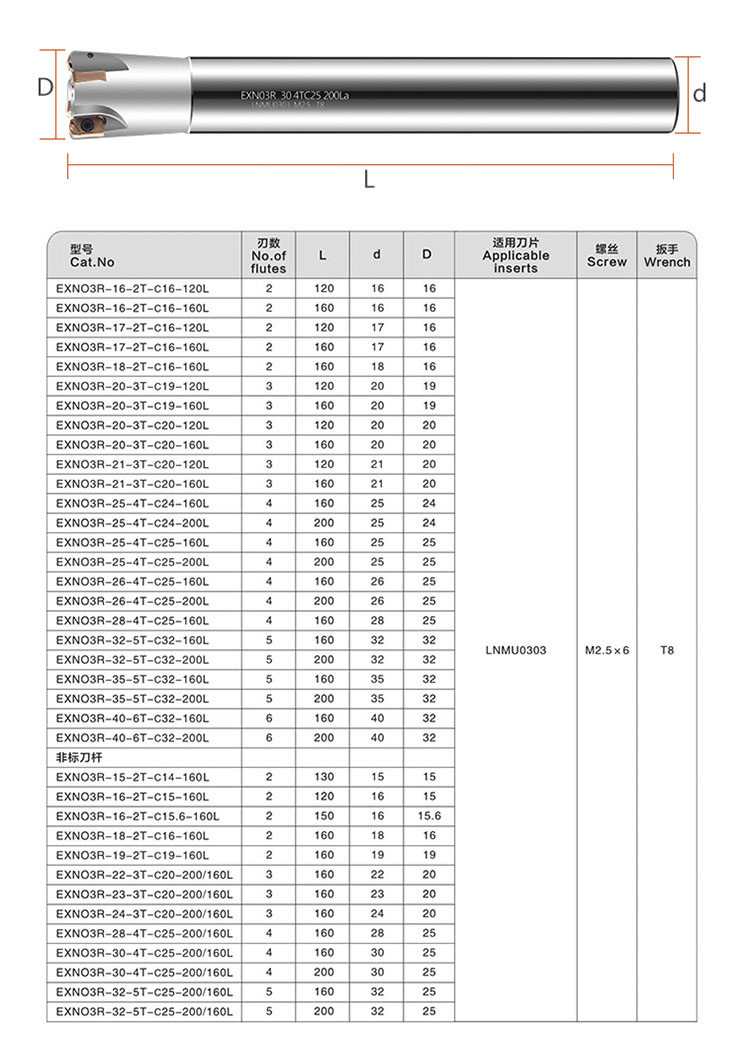

Ocut CNC Tool Holder EXN03R Rough Double-Sided Milling Tool Holder LNMU0303 Double-Sided Milling Insert Fast Feed Milling Tool Holder

Quenching and hardening to enhance service life

It is hardened by vacuum quenching and is not easy to deform, which improves the service life and stability of the tool holder and improves processing efficiency.

When the workpiece is positioned on the center hole at both ends for static grinding, the distance between the ejection pin axis and the grinding wheel line remains unchanged, making the tool holder more concentric and round.

Ocut, Boring tools, Drill tools, Inserts, End mill, U drill, Turning holder, Tap, Cutting tools,

Ocut, Boring tools, Drill tools, Inserts, End mill, U drill, Turning holder, Tap, Cutting tools,